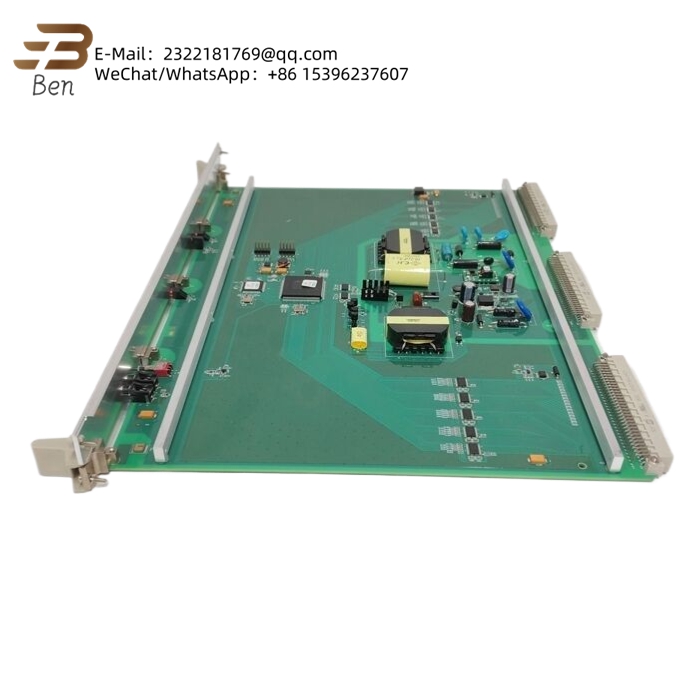

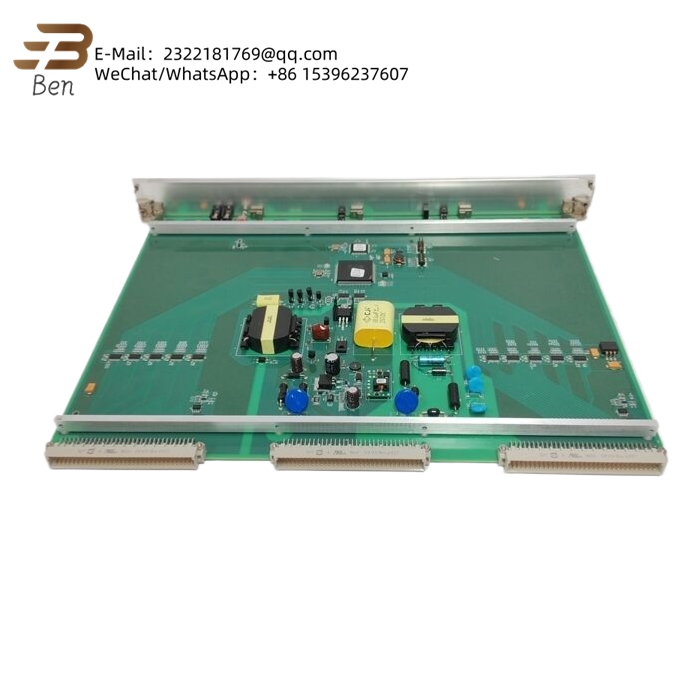

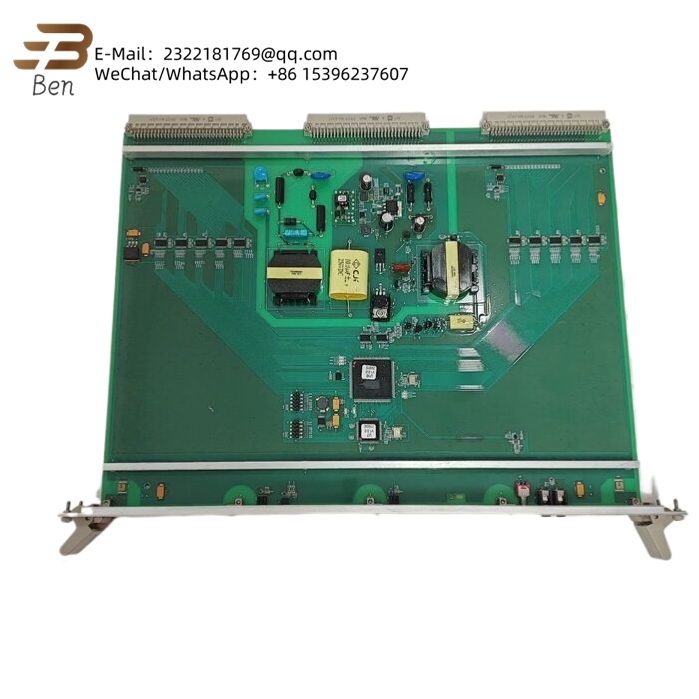

The ALSTOM V4561983-0100 V4559856 is an advanced industrial control system designed for mission-critical automation applications in demanding environments. As part of ALSTOM’s flagship control system portfolio, the V4561983-0100 V4559856 combines robust hardware architecture with sophisticated control algorithms to deliver unparalleled reliability and performance.

This cutting-edge system serves as the central nervous system for industrial automation, integrating seamlessly with PLCs, DCS, and other field devices through multiple industrial communication protocols. The ALSTOM V4561983-0100 V4559856 is particularly renowned for its application in large-scale process industries where system reliability and precision control are paramount.

Technical Specifications

| Parameter Name | Parameter Value |

|---|---|

| Model | V4561983-0100 V4559856 |

| Manufacturer | ALSTOM |

| Type | Industrial Control System |

| Processor | Quad-core 2.5GHz with hardware redundancy |

| Memory | 16GB ECC RAM (expandable to 32GB) |

| Storage | 256GB SSD + 1TB HDD (RAID 1) |

| I/O Capacity | Up to 2048 digital/512 analog points |

| Communication Protocols | Modbus TCP/IP, PROFIBUS DP, OPC UA, Ethernet/IP |

| Power Supply | 24VDC (18-36V range) with UPS support |

| Operating Temperature | -20°C to +60°C |

| Humidity Range | 5-95% non-condensing |

| MTBF | >100,000 hours |

| Certifications | SIL 3, ATEX, IEC 61508 |

Main Features and Advantages:

The ALSTOM V4561983-0100 V4559856 delivers exceptional system reliability through its fully redundant architecture, including dual power supplies, processors, and communication networks. This ensures continuous operation even during component failures or maintenance activities.

Advanced diagnostics: Comprehensive self-diagnostic capabilities and predictive maintenance features minimize downtime and optimize system performance. The V4561983-0100 V4559856 provides detailed system health monitoring through its intuitive engineering interface.

Engineering flexibility: Support for multiple programming languages (IEC 61131-3) and seamless integration with third-party devices makes the V4561983-0100 V4559856 adaptable to diverse industrial applications.

Application Areas:

- Power Generation: Turbine control and protection systems

- Oil & Gas: Pipeline monitoring and safety systems

- Chemical Processing: Batch control and safety interlocks

- Water Treatment: Plant-wide automation systems

- Transportation: Railway signaling and control

Related Products:

- ALSTOM STO1726KO1 Safety Torque Off (STO) module

- ALSTOM VPS 12004-102-03 Analog Input module

- ALSTOM DSI1817 TRVC062335000 Data transmission module

- ALSTOM STO1726KO1 Safety Torque Off (STO) module

- ALSTOM AL129A high-performance communication module

Installation and Maintenance:

Installation preparation: Ensure proper grounding and environmental conditions before installing the ALSTOM V4561983-0100 V4559856. Verify all system requirements including power supply specifications and communication network topology.

Maintenance recommendations: Perform quarterly system diagnostics and annual preventive maintenance checks. The V4561983-0100 V4559856 features hot-swappable components to facilitate maintenance without system shutdown.

Product Assurance:

Alstom offers a 12-month warranty for V4561983-0100 and V4559856. Each device undergoes strict factory testing and aging procedures to ensure reliable long-term operation.

Reviews

There are no reviews yet.